£ Enquire

The Kündig Perfect series represents the pinnacle of sanding technology, designed for precision, efficiency, and versatility. This sanding machine is ideal for a wide range of materials, ensuring exceptional surface finishes and user-friendly operation in demanding industrial environments.

TOUCH SCREEN & FEED SYSTEM:

A large part of the operating inputs on the flash are made using the touch screen which can be rotated by 270°. This makes it very easy to adjust oscillation, sanding belt and feed speed, sanding pad insert and release times, as well as storing and recalling sanding programs.

| Specification | Details |

|---|---|

| Sanding Width | 1350 mm |

| Workpiece Thickness Range | 3 – 200 mm |

| Feed Speed | 4 – 25 m/min |

| Main Motor Power | 11 – 22 kW |

| Brush Diameter | 200 mm |

| Machine Dimensions (L x W x H) | 3000 x 1900 x 1800 mm |

| Weight | 4000 kg |

|

Instead of pressure rollers, the upper feed belt can facilitate the sanding of smaller components Option for Uniq-S, standard for Flash |

|

For extra wide workpieces an additional lower feed belt can be provided Option for Uniq-S, standard for Flash |

|

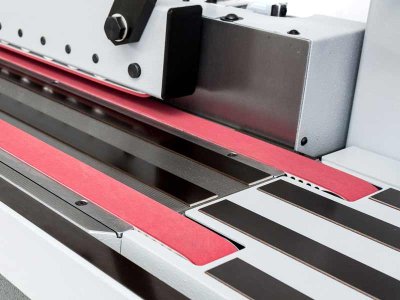

The grooved inlet platen allows the sanding of edges with overlapping veneers Option for Uniq, Uniq-S, Flash |

|

Semi round table for sanding curved pieces against the rubber covered driving roller Option for Uniq, Uniq-S, Flash |

|

Extra table with mandrel and abrasive bobbins for external and internal shapes Option for Uniq, Uniq-S, Flash |

|

Easy handling of large panels thanks to the telescopic support rail Option for Uniq, Uniq-S, Flash |

|

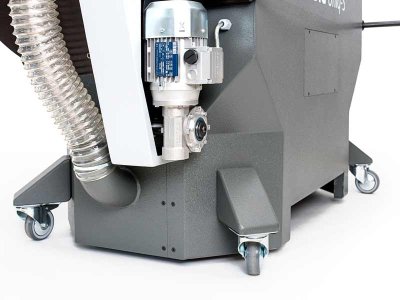

Increased flexibility and movability thanks to four transport wheels Option for Uniq, Uniq-S, Flash |

|

Steplessly abrasive belt speed for extremely sensitive surfaces or material with a low melting point. Option for Uniq-S, standard for Flash |

|

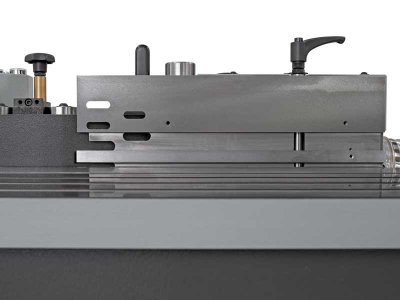

Special sanding pad inserts are available, such as an extra hard sanding pad for extended sanding of solid wooden edges or a ceramic sanding pad for heavy calibration tasks Option for Uniq, Uniq-S, Flash |

|

Different handling and working table extensions are available, even custom versions Option for Uniq, Uniq-S, Flash |

*Your quote will be submitted via the checkout section.

To speak to one of our experts, please call our office on 023 8065 3329.

| Net weight | 490kg |

|---|---|

| Floor space | 1150x800mm |

| Working level | approx. 830mm (solid sanding side respectively) |

| Belt length | 2000mm |

| Belt width | 150-200mm |

| Common internal tube & an outlet - dia. | 10mm |

| Belt driving motor | 3kW (4HP) |