£ Enquire

The Altendorf F45 is considered the best sliding table panel saw in the world. A machine that is built to your exact requirements by a manufacturer that introduces new technology and raises the bar for others to follow.

All operator controls are at eye level for ease. Functions such as the control of up to four axes – specifically height & tilt (up to 46 degrees to either side)* of the saw unit and the CNC rip fence* and crosscut fence* are already included. The ProDrive control panel automatically corrects the positioning of the rip fence* when the saw is tilted. When working with large pieces, there is a vacuum clamping control system* in the sliding table designed to secure workpieces. The ProDrive also comes with a 99 program memory.

*with corresponding optional equipment.

Starting with a 7” touchscreen and keyboard for entering numerical dimensions and specifications, the EvoDrive offers efficiency as standard. Controlling up to four axes, including saw blade tilt (up to 46 degrees) to either side*. Setting the EvoDrive apart from the ProDrive is its pre-installed application technology: for example defining inside and outside dimensions automatically from the material data thickness supplied. Additional features include grooving, incremental dimension and bevel rip features which should simplify your work, and is complemented by the compound mitre function & tool management system. The EvoDrive can store 999 rapidly retrieved programmes.

*with corresponding optional equipment.

Meet the most advanced and comprehensive control for sliding table saws. The ElmoDrive combines ease of use, practical and ergonomic operation without equal. The 12” touch screen has easy access to a calculator, geometric shapes, compound mitre and tool management systems in an easy to use system. As with the Pro & Evo Drives, the ElmoDrive of course gives motorised control of all axes and the ability to tilt the saw unit by up to 46 degrees on either side.* For functions you might regularly return to, the lower part of the display can be used to store these for additional efficiency. This is the only control unit that can be linked with a cut compensation package.

*with corresponding optional equipment.

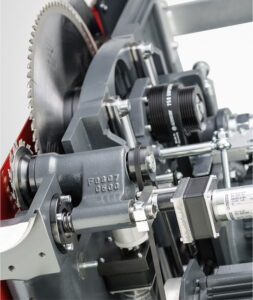

Drives for one-way tilt with manual speed adjustment. The motors are manufactured especially to Altendorf’s specifications and have been optimised for use in sliding table saws. The Altendorf F45 has a number of motors manufactured specifically for this machine.

They provide up to 20% more torque than conventional electric motors with no increase in power consumption. The three-speed units operate at 3 000, 4 000 and 5 000 rpm and are adjusted manually. The Vario-drive motors offer infinitely variable speed control between 2, 000 and 6, 000 rpm. Matching speed precisely to the material increases not just cutting quality, but also the service life of your saw blades, which, in turn, helps to reduce your costs.

The choice of motors are as follows:

For One-Way Tilt saws

For Two-Way Tilt saws

With electronic vertical and lateral adjustment, programmable scorer blade height, rapid deploy and retract and 0.75 kW (1 HP) motor (8 200 rpm). For retrofitting only to machines designed to accommodate a scorer unit.

With motorised vertical, lateral and cutting width adjustment, including saw blade, programmable scorer blade height, rapid deploy and retract, saw blade width display and 0.75 kW (1 HP) motor running at 8,200 rpm with one-way tilt or 6,000 rpm with two-way tilt. For retrofitting only to scorer-unit-ready machines. On one-way tilt machines it is possible to specify a 3-axis scorer with park positioning so you can use a 550 diameter blades on your Altendorf F45 without removing the scorer.

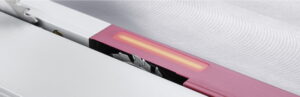

The scorer ensures chip-free undersides when working with laminated panels. The RAPIDO system makes adjusting the cutting width straightforward and enables this step to be completed in no more than three minutes. This can save you up to 30 minutes as compared with conventional scorer systems because it does away with the tedious process of mounting two-part scorer blades with spacer disks entirely. Adjustment is continuous and precise, so the RAPIDO can be fine-tuned to match any main blade.

Particularly energy-efficient LEDs render the hazard area around the scorer highly visible.

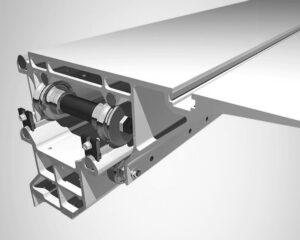

The Altendorf sliding table is renowned for its smooth, precise running. The large dumbbell rollers guide the moving table with absolute precision between the hard-chromed guide bars. Robust though it is, the table responds to even a light touch, gliding smoothly and securely as if on rails. And it retains this ease of movement even after decades of hard work, dust and dirt.

The sliding table can be manufactured in the following lenghts:

The motorised servo drive for the sliding table moves even the heaviest of workpieces back and forth easily during cutting, taking the physical strain off your body – and your back in particular. The electronic sensor control handle responds to the lightest of touches, so you can maintain an upright and relaxed posture throughout the cutting operation. The TIP-SERVO-DRIVE cannot be used in combination with the on/off switches on sliding table option or the vacuum clamping in sliding table option.

The STEG second support makes sizing large panels more straightforward for the user.

Altendorf is the first in the world to apply proven vacuum clamping technology to sliding table saws. The system, which is integrated into the sliding table itself, has at its heart a powerful vacuum pump that generates a vacuum via pairs of suction grippers arranged in the sliding table. The various suction zones positioned along the length of the sliding table can be activated individually at the touch of a button, allowing the vacuum to be matched optimally to each workpiece.

Panels of wood, plastic and non-ferrous metals remain securely in position on the sliding table throughout even complex cuts such as angles, long mitres and cuts to an outside dimension. Another touch of a button is all it takes to release the workpiece. Vacuum clamping improves reliability, precision and convenience and helps to eliminate manual operating errors.

All table lengths feature the same five pairs of suction grippers. Each pair can be activated separately.

Additional pairs of suction grippers are available on request.

Not compatible with TIP-SERVO-DRIVE.

Mount the On / Off switches for the main blade and scorer onto the table.

The crosscut fence with fixed 90° angle allows precision cuts on workpieces of different lengths and formats. The fence can be easily slid from the front to back position without lifting. The basic specification includes stops to 3 200 mm, adjustable using the graduated scale.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings applied. The central measuring and display unit calibrates the entire system in one operation. High-capacity batteries and a charger are included.

This patented Altendorf fence, with integral length compensation, can make both square cuts and mitre cuts. The mitre angle can be adjusted continuously over a range of 49° with a graduated scale and the robust, free-sliding zero-play flip stops can be positioned individually at any distance up to a maximum of 3 500 mm. The outer stop docks into the roller-stabilised telescopic extension for distances longer than about 1 700 mm. When cutting mitres, length compensation means measurements to the stops are accurate whatever the angle. Simply slide the fence to the desired angle, line up the pointer with the same angle on the length compensation scale, then set the flip stop to the length required.

For 1/10 mm accuracy when setting the length dimension. The display shows all stop settings applied. The central measuring and display unit calibrates the entire system in one operation. High-capacity batteries and a charger are included. The DIGIT LD also displays the angle digitally, enabling a level of precision of +/− 1/100°. The length dimension is calculated automatically as a function of the mitre angle. With integral length compensation. Including two flip stops and fine adjustment.

Accurate and wear-free, this system features a robust 90° locking mechanism that ensures the right-angle position is absolutely repeatable. The fence can be angled by up to 47° in either direction. The integrated digital display shows the angle with an accuracy of 1/100° for optimal precision. Also included is length compensation, which is simply set using a scale when the fence is angled. Stops to 3 500 mm.

Developed specifically for the new parallelogram cross slide (PQS), this display unit (90 mm diagonal) shows the distance to all stops digitally at the same time. Length compensation is straightforward once the fence has been set to the required angle. The fine adjustment of the distance to the stops is accurate to 1/10 mm and the angle is displayed as in the standard parallelogram cross slide. This reduces set up time to an absolute minimum. The high capacity batteries can be recharged very quickly using the integral charger provided. The DIGIT LD displays the angle digitally, enabling a level of precision of +/− 1/100°. The length dimension is calculated automatically as a function of the mitre angle. Including two flip stops and fine adjustment of the angle.

The CNC crosscut fence UNO 90, which is fixed in the 90° position, makes it possible to complete both square cuts and mitre cuts with great precision. The flip stop has a maximum travel of 1 900 mm. If greater length is required, the extension supplied can be fitted manually to give a maximum dimension of 2 900 mm.

This fence features two CNC stops with a maximum travel of 3 500 mm. It is fixed in the 90° position. Workpieces can be positioned against either side of the fence. The CNC crosscut fence DUO 90 is not compatible with the F 45 ProDrive control unit.

The DUO Flex fence can be angled manually by up to 47° for easy and convenient square cut and mitre cuts. It includes automatic length compensation and two motorised flip stops (travel to 3 500 mm). It is not necessary to lift the fence to switch between the front and rear positions on the cross slide. Workpieces can be positioned against either side of the fence, which makes it possible to complete compound mitres and mitre cuts at acute or obtuse angles in a single operation. The CNC crosscut fence DUO Flex is not compatible with the F 45 ProDrive control unit.

Setting the fence manually is easy; the precision fine adjustment makes for great accuracy. The hard-chromed round bar system ensures the fence moves smoothly. The rip fence can be swung away below table level in one action when preparing to divide large panels.

Digital cutting width display for the rip fence with manual fine adjustment. This electronic measuring system ensures rapid and precise adjustment of the rip fence. Recurring dimensions can be reproduced exactly and checked on the DIGIT X display. The correction for the rip fence position is shown digitally on the machine control unit’s LCD display when working with the saw blade tilted. The system is not subject to wear and is unaffected by dust. Dimensions are corrected automatically when the fence is switched between the up-right and the flat position.

The CNC rip fence has a traverse speed of 250 mm/sec. and an accuracy of +/–1/10 mm. The high-precision five-point recirculating ball screw system is low maintenance and, along with the motor, is well protected by its integration into the aluminium profile. The fence detects its position automatically, especially in the danger area around the saw blade, and has an emergency cut-out to prevent the risk of crushing. Dimensions are corrected automatically when the fence is switched between the upright and the flat position or when working with the saw blade tilted.

*You quote will be submitted via the checkout section

If you wish to speak to an Altendorf expert please call our office on 023 8065 3329.

| Base Motorised rise/fall and tilt adjustment | (0 – 46°) for main saw blade with automatic cutting height correction when the saw blade is tilted |

|---|---|

| Base Eye-level Control Unit | Swivel-mounted |

| Base Sliding Table | Table length 3,000 mm |

| Base Rip Fence | Manual adjustment using graduated scale, includes fine adjustment, cutting width 1,000 mm |

| Base Crosscut fence | Fixed 90° angle, manual adjustment using graduated scale up to 3,200 mm |

| Base Saw Blade Projection | 154 mm |

| Maximum Saw Blade Diameter 450 mm | 450 mm |

| Base Motor | Motor rating 5.5 kW (7.5 HP) with three speeds (3/4/5,000 rpm) |

| Base Clamping System | AKE tool clamping system for the main saw blade |

| Base Working Height | 91 cm |