£ Enquire

The PEGAS 230×280 GH-LR Gravitational Bandsaw is meticulously crafted for both vertical and angular material cutting. It offers seamless angle adjustments, ranging smoothly from 0 to 60 degrees to the right and from 0 to 45 degrees to the left. This machine is ideally suited for both piece production and small series manufacturing. Thanks to its robust construction, it can effortlessly handle a wide array of profiles and various materials.

The PEGAS 230×280 GH-LR Bandsaw is designed for reliable and efficient cutting with minimal maintenance. Its robust construction, user-friendly features, and high performance make it an ideal choice for a range of cutting needs.

*Your quote will be submitted via the checkout section

To speak to one of our experts, please call our office on 023 8065 3329.

| Code | Description | Type | |

|---|---|---|---|

| 230-MLC | Motor with low consumption (0,75/1,1Kw) | ST | |

| 230-M2V | Two speed motor with a gearbox. (0,9/1,4Kw) | OP |

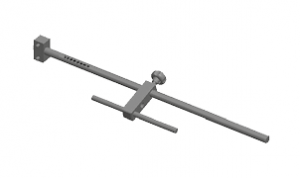

| 230-OZM | Measuring end stop which is mounted directly to the machine, length 1m. | ST |

| 240-CK | Cleaning brush of blade, driven passively (driven by sawing blade). | ST |

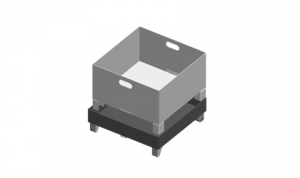

| BOX-PCS | Box for cutted pieces with emulsion draining to the waterproof tank. | O |

| BOX-TRI | Box for the chips with emulsion draining to the waterproof tank. | O |

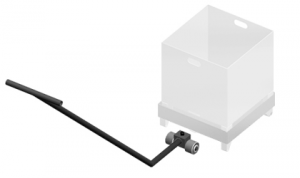

| BOX-TAH | Tool for manipulation with BOX-PCS and BOX-TRI. | O |

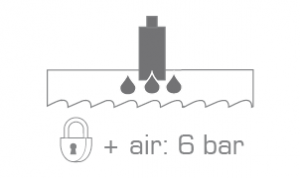

| MINI LUBE 27-34 | Wasteless lubricating system, instead of emulsion cooling, specially for cutting profiles and non-ferrous metals, necessary supply of pressed air 6 Atm. | OP |

| LASER LINE | Laser indicator of cut position. | OP |

| 230-QPARTS | Set of easy worn away spare parts: * 4 pcss: hard-metal plate 235 * 4 pcss: bearing 608 2Z * 10 pcs: cleaning brush 240-CK | O | |

| 230-SET M42 | Set of 10 blades in M42 quality – with customer’s choice of teeth. 2720x27x0,9 | O | |

| 230-SET M51 | Set of 10 blades in M51 quality – with customer’s choice of teeth. 2720x27x0,9 | O | |

| 230 – NAV | Manual instruction – printed version. | O |

| PAL EUR | Packing on the palette 0,8 m x1,2 m. | O | |

| OBAL1 | Package – wooden box 1,2 m x 2,0 m. | O | |

| OBAL-230/OSB | Packing in wooden box. | O | |

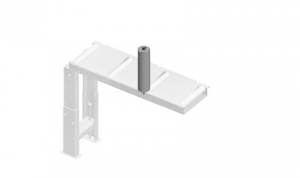

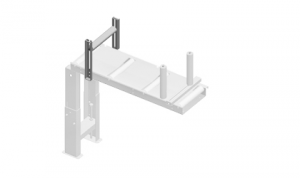

| 230 RDZ | Output connecting part of the roller conveyor RD – ensures angle cuts of the machine, length 1000 mm, width 290 mm, bearing capacity 200 kg/m, adjustable leg includedd in price. | O |

| 230 RDP | Input connecting part of the roller conveyor RD-ensures angle cuts of the machine, length 1000 mm, width 290 mm, bearing capacity 200 kg/m, adjustable leg includedd in price | O |

| RD 1000/290 | Roller table. Length 1000 mm, width of cylinders 290 mm, capacity 200 kg/m, adjustable leg and console for connecting with machine included in price. | O |

| RD 2000/290 | Roller table. Length 2000 mm, width of cylinders 290 mm, capacity 200 kg/m, adjustable leg and console for connecting with machine included in price. | O |

| RB 200 | Side vertical fix cylinder, height 200 mm, monted on the RD tables | O |

| RD VR-290 | Robust cylinder length 290 mm with the bearing for RD roller coneyor. The capacity of roller table increased from 200 kg/m to 400 kg/m | O |

| RBS 200/290 | Side vertical movable cylinder, height 200 mm, working only with RB. | O |

| RHS 290 | Horizontal cylinder , working only together with RB + RBS for bundle fixing, length of cylinder 290 mm | O |

| OZ 0000 | Second movable stop for OZ. | O |

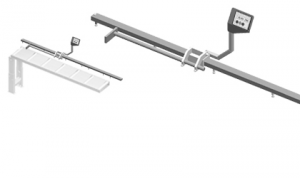

| OZ 1000 | Mechanic measuring system with the meter L = 1200 mm. | O |

| OZ 2000 | Mechanic measuring system with the meter L = 2200 mm. | O |

| OZ 3000 | Mechanic measuring system with the meter L = 3200 mm. | O |

| OZ 4000 | Mechanic measuring system with the meter L = 4200 mm. | O |

| OZ 5000 | Mechanic measuring system with the meter L = 5200 mm. | O |

| OZ 6000 | Mechanic measuring system with the meter L = 6200 mm. | O |

| OZD 1000 | Mechanic measuring system with digital display 1 meter long. | O |

| OZD 2000 | Mechanic measuring system with digital display 2 meter long. | O |

| OZD 3000 | Mechanic measuring system with digital display 3 meter long. | O |

| OZD 4000 | Mechanic measuring system with digital display 4 meter long. | O |

| OZD 5000 | Mechanic measuring system with digital display 5 meter long. | O |

| OZD 6000 | Mechanic measuring system with digital display 6 meter long. | O |

| RDN | Support for RD. | O |

| R290 | Movable cylinder, adjustable height, width 290 mm, capacity 200 kg. | O |

| Cutting Parameters | Shortest Cutting – 20mm Smallest Divisible Diameter – 2 mm Shortest Rest During One Cut – 22mm |

|---|---|

| Performance Parameters | Drive of the blade – 0,9/1,4 kW Pump of the cooling emulsion – 0,05 kW Total input – 1,54 kW Cutting speed – 35/70m/min Diameter of the blade – 2720x27x0,9mm Electric connection – 3x400V, 50 Hz, TN-S |

| Working Movements | Feed of the Frame to the cut – By its own weight, the speed is regulated by a by-passing valve and hydraulic cylinder Feed of the material – Manually Clamping of material – Hydraulically Bend tension – Manually Cleaning of the blade – Pasive cleaning brush |