£ Enquire

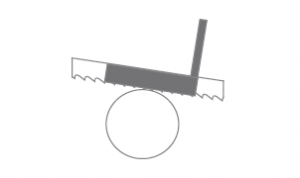

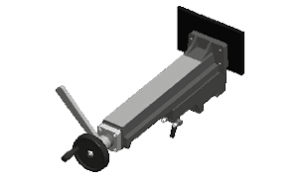

The PEGAS 300×320 SHI-LR Semi-Automatic Bandsaw, equipped with hydraulic control, is expertly crafted for precision cutting. This bandsaw excels in making perpendicular and angular cuts, with the ability to continuously adjust angles from 0 to +60 degrees to the right and from 0 to -45 degrees to the left. Changing the cutting angle is a breeze, thanks to the quick-release lever. This versatile machine is ideal for both piece and small series production, and its sturdy construction allows it to handle a wide range of material qualities, including stainless steels and tool steels, in various forms such as profiles and solid semi-finished products.

Recommendations of band blade producers should be followed when choosing to cut full material, as their dimensions are limited by the available size of the teeth for the specific type of the band.

The PEGAS 300×320 SHI-LR is designed for reliable and efficient cutting with minimal maintenance. Its robust construction, user-friendly features, and high performance make it an ideal choice for a range of cutting needs.

*Your quote will be submitted via the checkout section

To speak to one of our experts, please call our office on 023 8065 3329.

| Code | Description | Type | |

|---|---|---|---|

| MITSUBISHI HMI 4,5″ | Control system MITSUBISHI with display 4,5“ | ST | |

| F | Motor and frequency converter for a fluent change of the circumferential speed of the blade. | ST |

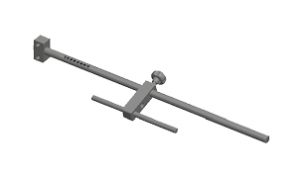

| OZM | Measuring end stop which is mounted directly to the machine, length 1m. | ST |

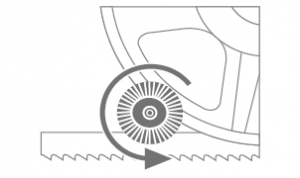

| 300-PCK | Cleaning brush of blade, driven passively (driven by pulley). | ST |

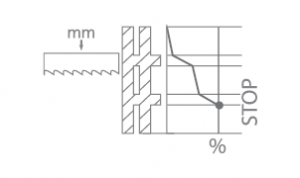

| PEGAS-BRP | Electronical regulation of the down-shift. | ST |

| 300-DPP | Automatic end stop of the upper position. | ST |

| 300-PUD | Digital indicator of adjusted angle. | OP |

| 300-SRZ | Vice behind the cut. Hydraulic clamping of the material behind the cut. | OP |

| 300×320 HP | Hydraulical upper vice. Hydraulic upper clamping tighten the material in vertical sense by the hydraulic cylinder. | OP |

| 300-RTS | Regulation press of vice. | OP |

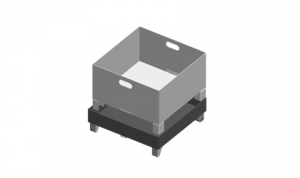

| BOX-PCS | Box for cutted pieces with emulsion draining to the waterproof tank. | O |

| BOX-TRI | Box for the chips with emulsion draining to the waterproof tank. | O |

| BOX-TAH | Tool for manipulation with BOX-PCS and BOX-TRI. | O |

| LIGHT L1 | Lighting of working space. | OP |

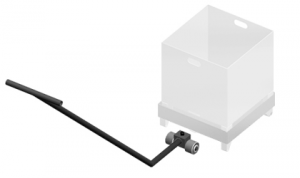

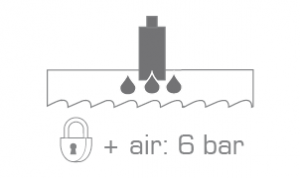

| MINI LUBE 27-34 | Wasteless lubricating system, instead of emulsion cooling, specially for cutting profiles and non-ferrous metals, necessary supply of pressed air 6 Atm. | OP |

| 300×320-QPARTS | Set of easy worn away spare parts: * 4 pcss: hard-metal plate 235 * 4 pcss: bearing 608 2Z * 10 pcs: cleaning brush 240-CK | O | |

| 300×320-SET M42 | Set of 10 blades in M42 quality – with customer’s choice of teeth. 3660x27x0,9 | O | |

| 300×320-SET M51 | Set of 10 blades in M42 quality – with customer’s choice of teeth. 3660x27x0,9 | O | |

| 300 – NAV | Manual instruction – printed version. | O |

| PAL1 | Packing on the palette 1,2 m x 2,0 m. | O | |

| OBAL1 | Package – wooden box 1,2 m x 2,0 m. | O | |

| OBAL-300 | Packing in the wooden cage. | O | |

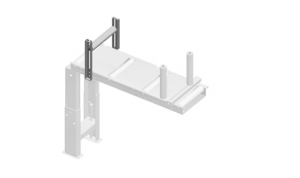

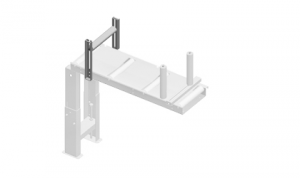

| 300-LR-RDP | Input connecting part of the roller conveyor RD – ensures angle cuts of the machine, length 1000 mm, width 390 mm, bearing capacity 200 kg/m, adjustable leg includedd in price. | O |

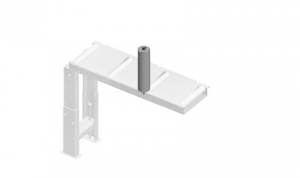

| RHS 390 | Horizontal cylinder , working only together with RB + RBS for bundle fixing, length of cylinder 390 mm. | O |

| 300-LR-RDZ | Output connecting part of the roller conveyor RD-ensures angle cuts of the machine, length 1000 mm, width 390 mm, bearing capacity 200 kg/m, adjustable leg includedd in price. | O |

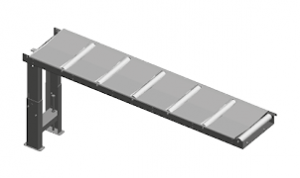

| RD 1000/390 | Roller conveyor. Length 1000 mm, width of cylinders 390 mm, capacity 200 kg/m, adjustable leg included in price. | O |

| RD 2000/390 | Roller conveyor. Length 2000 mm, width of cylinders 390 mm, capacity 200 kg/m, adjustable leg included in price. | O |

| RD VR-390 | Robust cylinder length 390 mm with the bearing for RD roller coneyor. The capacity of roller table increased from 200 kg/m to 400 kg/m | O |

| RB 200 | Side vertical fix cylinder, height 200 mm, monted on the RD tables | O |

| RBS 200/390 | Side vertical moovable cylinder, height 200 mm, working only with RB. | ST |

| RHS 290 | Horizontal cylinder , working only together with RB + RBS for bundle fixing, length of cylinder 290 mm | O |

| OZ 0000 | Second movable stop for OZ. | O |

| OZ 1000 | Mechanic measuring system with the meter L = 1200 mm. | O |

| OZ 2000 | Mechanic measuring system with the meter L = 2200 mm. | O |

| OZ 3000 | Mechanic measuring system with the meter L = 3200 mm. | O |

| OZ 4000 | Mechanic measuring system with the meter L = 4200 mm. | O |

| OZ 5000 | Mechanic measuring system with the meter L = 5200 mm. | O |

| OZ 6000 | Mechanic measuring system with the meter L = 6200 mm. | O |

| RDN | Support for RD. | O |

| R390 | Movable cylinder, adjustable height, width 390 mm, capacity 200 kg. | O |

| 300×320-RDP 1000/350 | Input robust connecting conveyor, there is a special shape for angle turning of the machine. Width of cylinders 350 mm, length 1000 mm., capacity 1000 kg/m. | O |

| 300×320-RDZ 1000/350 | Output roller conveyor, there is a special shape for angle turning of the machine. Width of cylinders 350 mm, length 1000 mm, capacity 1000 kg/m. | O |

| RDT 1000/350 | Robust roller conveyor with a gutter which prevents leakage of emulsion on the floor, width of cylinders 350 mm, length 1000 mm, 3 rollers, capacity 1000 kg/m. Attention: this roller table cannot be mounted directly on the input to the saw. | O |

| RDT 2000/350 | Input or output robust roller conveyor with a gutter which prevents leakage of emulsion on the floor. Width of cylinders 350 mm, length 2000 mm, 5 rollers, capacity 1000 kg/m. | O |

| 300×320-V | Roller of roller table RDT put into gap. | O |

| 300×320-RBS | Side movable cylinder, height 200 mm, diameter 67 mm it is avalible only with RB. IMPOSSIBLE ASSEMBLE ON VD1 ROLLERTABLES. | O |

| 300×320-RB | Side support fixed cylinder, height 200 mm, diameter 67 mm including support – length 350 mm. IMPOSSIBLE ASSEMBLE ON VD1 ROLLERTABLES. | O |

| 300×320-OZP | Mechanical fixed stop with ruler and scale line. Works only with OZP-L. Impossible use for CNC !!! IMPOSSIBLE ASSEMBLE ON VD1 ROLLERTABLES. POSSIBLE ONLY WITH ROLLER TABLE TYPE RDT/TDT | O | |

| 300×320-OZP-D | Mechanical fixed stop with digital display of setting length. Impossible use for CNC !!! Works only with OZD-L. IMPOSSIBLE ASSEMBLE ON VD1 ROLLERTABLES. POSSIBLE ONLY WITH ROLLER TABLE TYPE RDT/TDT. | O | |

| 300×320-OZP-L-RDZ | Measuring system for OZP mounted on FIRST roller table. | O | |

| 300×320-OZP-LE-RDZ | Measuring system for OZP mounted on FIRST AND EITHER LAST roller table. | O | |

| 300×320-OZD-L-RDZ | Measuring system for OZD mounted on FIRST roller table. | O | |

| 300×320-OZD-LE-RDZ | Measuring system for OZD mounted on FIRST AND EITHER LAST roller table. | O | |

| 300×320-OZP-L 1000 | Measuring system for OZP mounted on 1 m roller table. | O | |

| 300×320-OZP-L 2000 | Measuring system for OZP mounted on 2 m roller table. | O | |

| 300×320-OZP-LE 1000 | Measuring system for OZP mounted on LAST 1 m roller table in the setup. | O | |

| 300×320-OZP-LE 2000 | Measuring system for OZP mounted on LAST 2m roller table in the setup. | O | |

| 300×320-OZD-L 1000 | Measuring system for OZD mounted on 1 m roller table. | O | |

| 300×320-OZD-L 2000 | Measuring system for OZD mounted on 2 m roller table. | O | |

| 300×320-OZD-LE 1000 | Measuring system for OZD mounted on LAST 1 m roller table in the setup. | O | |

| 300×320-OZD-LE 2000 | Measuring system for OZD mounted on LAST 2 m roller table in the setup. | O |

| Cutting Parameters | Shortest Cutting – 3mm Smallest Divisible Diameter – 5 mm Shortest Rest During One Cut – 30mm |

|---|---|

| Performance Parameters | Drive of the blade – 2,4 kW Drive of the hydraulic agregate – 0,44 kW Pump of the cooling emulsion – 0,09 kW Cooling – 0,03 kW Distributor – 0,25 kW Total input – 6,5 kW Cutting speed – 20-100m/min Diameter of the blade – 3660x27x0,9mm Electric connection – 3x400V, 50 Hz, TN-S |

| Working Movements | Feed of the Frame to the cut – Hydraulically Feed of the material – Manually Clamping of material – Hydraulically Bend tension – Manually Cleaning of the blade – Pasive cleaning brush |